Here we discuss crimping techniques that can take your rifle’s accuracy to the next level.

Crimping a bullet in place might be the last phase of the reloading process, but it certainly isn’t the least important. In a number of instances, it’s absolutely necessary; other times, it’s optional and, sometimes, it should be avoided altogether. Knowing which type of crimp to use is important … and knowing whether to use a crimp at all can be a complete game changer.

Basic reloading techniques dictate that a straight-walled cartridge requires a roll crimp—which curls the case mouth into the bullet—to keep the projectile from moving deeper into the case under recoil or, in the case of a revolver, moving out of the case and locking up the cylinder.

However, the use of a roll crimp requires a bullet with a cannelure, or a crimping groove, or else you run the risk of bulging the case, deforming the bullet … or both. If your chosen projectile doesn’t have a cannelure, a taper crimp—one which squeezes the case wall radially inward against the shank of the bullet—is the only way to prevent damage to your case or projectile.

The handgun cartridges I shoot most—.38 Special, .45 ACP and .45 Colt—are all crimped in some fashion, I don’t crimp bottlenecked rifle cases unless absolutely necessary. The lever gun cartridges—at least those that use a tubular magazine—get a good roll crimp in order to hold things in place, but I rarely use a roll crimp on my .308 Winchester, .300 Winchester Magnum, .470 Nitro Express or .22-250 Remington; the neck and its tension does the work for me.

Ramp up the recoil to the hard-kicking Weatherby cartridges, or the .500 Jeffery and .505 Gibbs, and those cartridges in the magazine can have their bullets driven deeper into the case from the aggressive recoil.

Solution: Proper Crimp

In fact, it was a problem-solving conversation with my buddy, Bob Rose—who has a newly built .505 Gibbs—and is having all sorts of trouble keeping his bullets at the depth he seated them. He’s used several different bullets, with cannelures of varying depth, having applied roll crimps from what would be considered light, to “this time you’re not going anywhere,” only to see the same results: Those cartridges in the magazine had their bullets sunk deep into the case.

We covered a number of scenarios, as I’ve loaded rather extensively for both the .500 Jeffery and .505 Gibbs—both have hellacious recoil—and have solved a good number of problems with both. Looking at Bob’s reloading technique, I saw no flaws in the process or the logic; instead, it was an examination of the magazine boxes of the respective rifles we were loading for that I feel is to blame here.

You see, I loaded the vast majority of the .505 Gibbs and .500 Jeffery ammunition for rifles that had a magazine box of specific geometry—that is, the side walls of the magazine box have a correlative “shoulder” to the cartridge in order to prevent the cartridge from slamming forward under recoil. In Bob’s case, it seems there’s a bit more room for play, and he’s seeing the nasty effects of the high level of recoil. He’s got a Lee Factory Crimp Die on order and hopefully that’ll help solve his ordeal without having to change the magazine box of his rifle.

Some folks use a crimp as a means of evening out velocity. Since I was a kid, I remember reading about how the Weatherby magnum’s cartridges were best served by using a roll crimp to achieve both consistent velocities and optimize accuracy. The theory is that the additional pressures built during the ignition phase—required to move the bullet out of the roll crimp—will help to generate a repeatable pressure curve, resulting in improved accuracy. Considering that so many factory loads are roll crimped—and not just Weatherby ammo—there might be some credence to this concept.

I’ve pulled apart several factory loads over the years and have found that some timeless component bullets, such as the Nosler Partition that have been offered as components since the 1940s without a cannelure, are offered to the OEM ammo manufacturers with a cannelure. This is presumably to meet a requirement for crimping the factory ammunition, though I have often wondered why that would be, as the match-grade ammo featuring Sierra MatchKings, Berger Match or Hornady ELD Match bullets had no such cannelure.

I started experimenting with what I’ll call “unnecessary crimping,” and I did find that, in some instances, it has helped to even out velocities. Though by my own admission, the situation depends more on the rifle and its chamber than it does some universal law regarding crimping.

So, what is the rule regarding a crimp on bottlenecked rifle cartridges? Providing there’s enough neck tension to properly hold the bullet in place—and by that I’ll say that the .300 Winchester Magnum, with a neck length of 0.264 inch is enough—I feel comfortable saying there’s no rule. If you feel that you’re seeing your bullets move as a result of recoil, try a firm roll crimp, or grab one of those undervalued Lee Factory Crimp Dies and see if that tool will even things out for you.

Trial And Error

Experimentation can be the key to success when it comes to reloading; the goal is to achieve repeatable results by any means necessary. Each rifle can present a different set of challenges, and I like to have a diverse set of tools when trying to get my ammo and rifle combination to perform the way I want.

Quite a bit of emphasis is put on varying seating depth, changing primer brands, minuscule changes in powder charge weight or even powder type, but if adding a crimp into the mix gives me one more tool in the box to get that rifle where I need it, I’m good with that. For a hunting rifle, the level of accuracy might not be the same as that of a long-range target shooter, but when you want the best, it’s smart to consider all options.

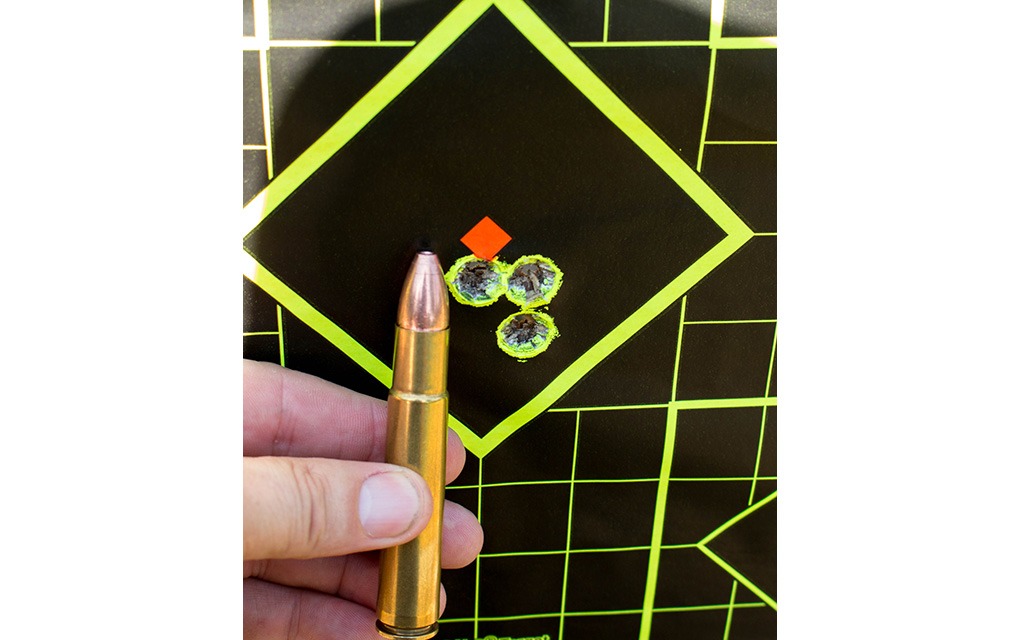

Try your pet load with and without a roll crimp, and see if you find any difference, for better or for worse. You might find an unexpected solution, making a good load even better. Use your chronograph to best observe the differences between crimped and un-crimped, and I’d wager that the one with the more consistent velocity figures will also be the most accurate.

Editor’s Note: This article originally appeared in the December 2022 issue of Gun Digest the Magazine.

More On Reloading:

Read the full article here