Images by the author

I have not had much experience with John Browning’s wunderkind, the .50 BMG. Let’s say that right up front. But I’ve always had a fascination with it, probably starting when I was a young pup, building plastic models of WWII aircraft and painting their “machine guns” a gunmetal color. I imagined what it would’ve been like to fire them.

Fast-forward several decades, with two reviews under my belt of an Armalite .50BMG bolt rifle. Then add to that my recent review of the HM Defense Sniper Rifle in that esteemed caliber. I guess you could say I had on-the-job training where the big .50 was concerned.

So, to travel down .50BMG Lane a little further, I thought it would be fun to do a quick review on reloading for this beast. I have been reloading a variety of calibers since the late 1970s, but I never had a reason to tackle the .50. That is, until one of our sons’ father-in-law bought that HM Defense rifle and wanted to tackle loading for it.

Tracy is a retired engineer and, as such, emphasizes precision. He builds some beautiful furniture, and has made a few shooting benches, one of which lives in my backyard range. He is very talented, and wanted to translate that to his 50GMB adventure. That would include reloading.

I contacted my friend at RCBS, who sent us one of their Ammomaster press kits and a jug of Hodgdon H.50BMG powder. Tracy already had cases and primers and had sourced bullets… tracers, of all things. THAT will be a fun shoot! He was good to go.

He set the press up and started the process. Reloading the .50BMG differs from reloading, say, the 308 that I’m familiar with, in terms of scale. Everything is huge. You need a press with a large ram – you need the 1 ½-inch die kit – with enough force to resize those ginormous cases. Let’s look at the press involved…

The Ammomaster is the largest press that RCBS makes. It has one main purpose… to reload .50BMG. You can use it for lesser calibers – it does take “normal” ⅞” dies – but it was designed for the 50. It has a 1 ½” ram and a 17-inch handle for cranking power. If a reloading press could be on steroids, this would be the one.

Here are a few features from the web page linked above:

- Uses standard 7/8 inch-14 thread dies and standard shell holders to load pistol or rifle calibers. Press is threaded 1 1/2”-12

- Load 50 BMG with the addition of the .50 BMG 1 1/2-inch Die Kit (88705)

- 1.5” diameter ram. Provides exceptional rigidity, alignment in the bore, and allows for modularity by accepting standard shell holders or those up to 50 BMG

- Massive 17.5” arm for top-of-the-line leverage

- Improved vs original AmmoMaster. Longer support columns, larger toggle block

- Includes press, press handle, primer catcher, and ram priming unit for seating small/large primers

- Proudly Made in the USA

A case trim die is included. File off anything above the top of the die.

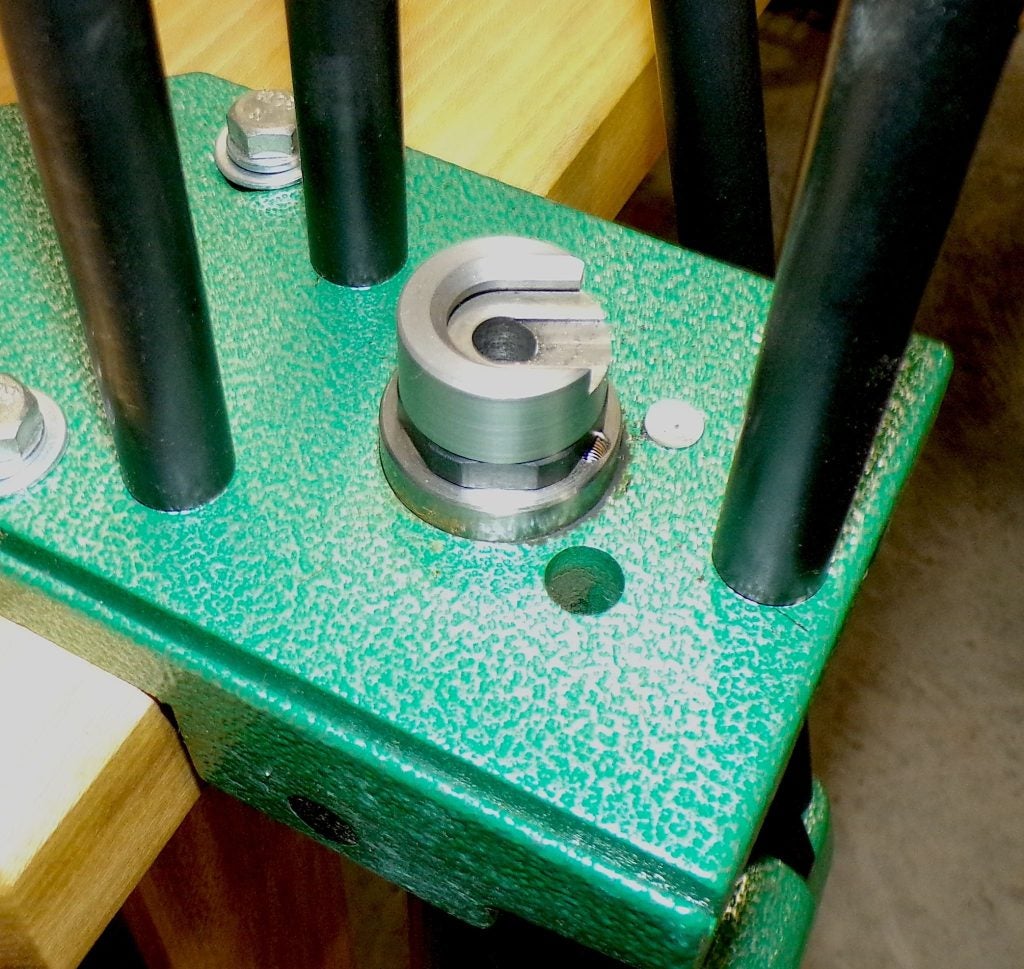

That inch-and-a-half-diameter ram is huge. This case holder doesn’t snap in; it screws down.

It’s interesting to note that this press doesn’t have all the bells & whistles that some presses come with. We have to remember that it is designed to perform one task… loading the .50BMG. When you are resizing a case that can hold 250 grains of powder and a 750-grain bullet, you need crunch power, and this press has that. It is truly awesome.

The Process

There really won’t be any new, earth-shaking news here in terms of the reloading process… It’s the same for the 50 as it is for my 308 or other rifle cartridges. As I said above, things are larger. That’s the main difference.

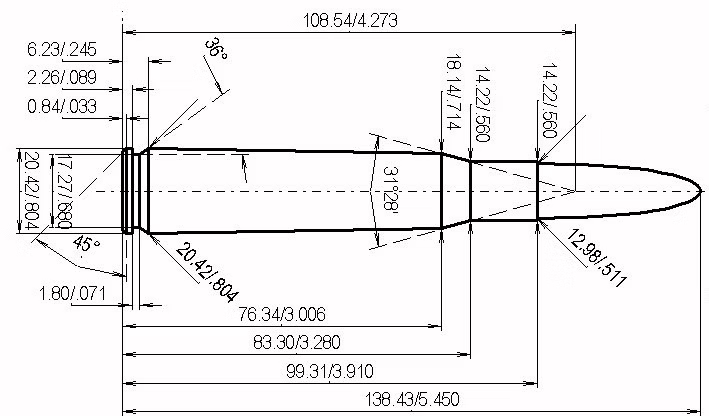

Image: xxlreloading.com. I am a member… It’s a great way to get access to dozens of loads, and it only costs twenty bucks for a year’s membership.

To load the big 50, here’s a Cliff Notes version of the drill:

- Inspect your cases. Annealed cases are best, as they have a bit of “give” when firing and resizing.

- Lube your cases, both outside and inside the case mouth. Don’t overdo it.

- Run the cases up into the decapping/resizing die.

- Prime the cases after installing the priming unit that came with the press. Make sure you’ve removed any military crimp, if one was applied, before attempting to seat new primers. There are several ways to do that.

- Charge the case with powder. The RCBS Matchmaster powder dispenser makes a great companion to the Ammomaster press. It uses two tubes and can measure to within .04-grain.

- Place a .510” bullet in the case mouth after swapping the resizing die for the bullet seater.

- Run the case up into the seating die, thereby seating and crimping the bullet.

- Again, inspect the loaded round. Make sure that: the bullet is tightly crimped; the shoulder is not displaced; the case overall length is within specs.

The above steps assume you’ve done your homework and have your dies properly adjusted. It’s easy to have the sizing die screwed down too far, which will obliterate the case shoulder… ask us how we know.

There is a learning curve, and Tracy is doing very well considering he’s never loaded anything remotely as large as this Panatella-sized boomer.

Resizing Die Adjustment – The Sharpie Method

Here is a method I use for all my rifle loading… no reason not to use it for the .50.

For the resizing die, first use a Sharpie to draw a vertical line on an empty case neck, from the shoulder to the mouth. Rub some lube sparingly on the case shoulder and body. Place the case in the shell holder, then back out the die by unscrewing it a half-inch or so. Run the case up into the die and screw the die down until you feel resistance. Pull the case out and screw the die in one turn. Run the case back up into the die. You should feel some resistance. Check whether your mark has been erased by sizing. Keep adjusting the die until the line is gone, right down to the shoulder. You have now neck-sized your case. If you are going to shoot all your brass in one gun, neck sizing should work. However, if you want a bit more freedom in terms of chambering in a dirty rifle chamber or firing the loads in another rifle, full-length sizing might be in order. Screw the die down another half to a full turn… experiment to find the proper amount to lower it. Now, you will have a full-sized case that should work in a dirty chamber or in your friends’ .50BMG rifle.

Bullet Seating Die

The best way to adjust the seating die is by using a loaded cartridge. Stick a loaded round in the shell holder and back the seating die out a few turns, and the seating stem out yet a few more turns… bring it up a half inch or so. Run the cartridge up into the die. Screw the die body down until it contacts the case. Turn the die down a half turn or so, which will apply a crimp to the case. Screw the seater stem down until it contacts the bullet nose and lightly tighten the nut. You’ve got basic adjustments accomplished. You can fine-tune bullet seating and crimp now, with very minute changes to the die and stem positions. Then, you can set the hex screw on the die ring and the bullet stem more tightly. Make sure the crimp is secure, and you should be good to go.

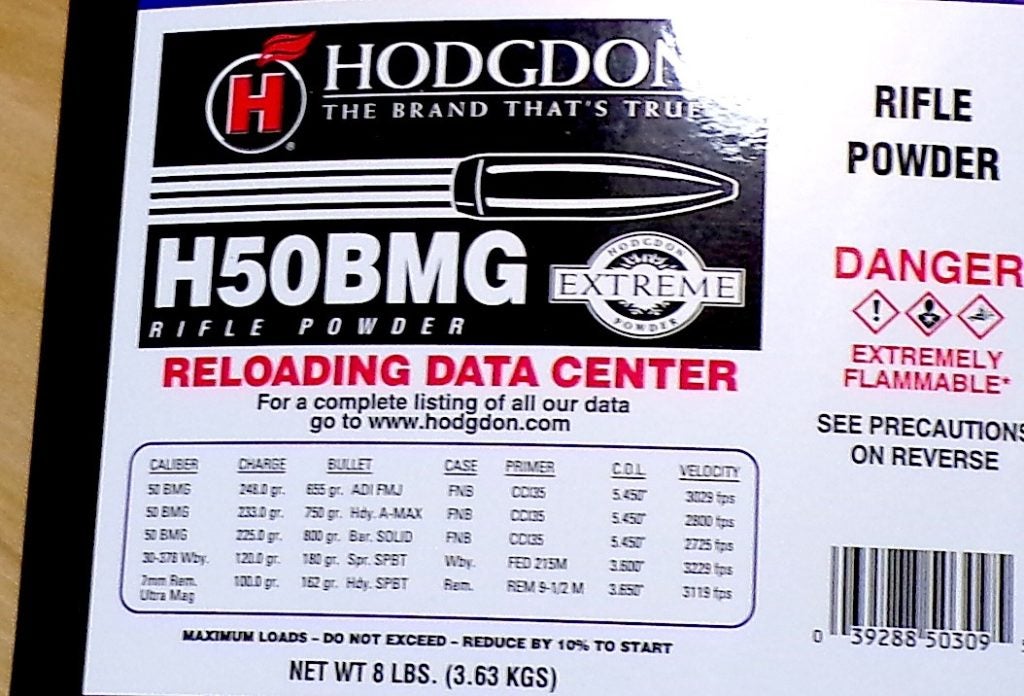

A Note About Powder

There is one thing that makes loading this big 50 fairly simple… It’s the choice of available powders. I’ll use the 308 again as an example. You could spend a whole day just deciding which of the multitude of powders out there to use. The .50? Not so much. You are limited to a very few powders, as this is a niche cartridge for reloading. Even though it is expensive, reloading is one way to truly enjoy your ginormous rifle. But be aware that your options will be limited. We settled on Hodgdon’s H.50BMG powder as mentioned above.

Cost

Speaking of cost, be prepared. The .50BMG will set you back about $4-$5 for an average factory-loaded round. OK, you bought some to start with, so now you have some cases saved… those are the biggest expense. Now, bullets. Tracy found pulled military 605-grain bullets for forty cents each… that’s pretty cheap. He ran them through a Lee bullet sizer to remove scratches and other imperfections from the pulling process. As for primers, he sourced 130 for about $70. These are not your normal large rifle… they are larger than that, as they need to be.

Notice the charge weights in the photo above… we’re talking about 225-250 grains for the bullets we have. All I can say is wow… I am a powder miser who likes to load about four grains for a 9mm target load. I could load about 63 9mms for one .50BMG. Wow… Please be prepared to spend some on powder. We’re talking about $430 for an 8-pound jug. You will get about 224 to 250 grain loads out of that jug. So, again, be prepared.

But still, you can shoot your reloads for a whole lot cheaper than factory ammo. That’s the bottom line. If you crank out loads for about $2 – $2.50 each, that means you can do more shooting for the same money. This is not going to be a mud-puddle-splashing plinking gun, but for serious target work, it can’t be beaten. You can shoot it more for the same amount of money you’d have spent on factory loads.

As I write this, the range where this rifle is shot is buried under a foot of snow with the access lane closed, so I don’t have any target photos to show. I am confident that, given the attention being paid to reloading details, the handloads will shoot at least on par with (or better than) factory loads.

Is there a .50BMG reloading press in your future? Could be. Several companies make them – we used the RCBS because it is one of the strongest presses out there. You can source components easily… not cheaply, but they are out there. If you are a serious .50BMG aficionado, you might want to consider adding this to your repertoire or going in with your shooting buddies to buy one. It is a way to shoot more for the same factory ammo dollar, which is always a good thing!

Read the full article here